32. De Novo Polymer Design

Keywords: MedeA environment, Polymer Expert, P3C, PEARL, de novo polymer design and optimization

Throughout the twentieth century, the availability of petrochemically derived synthetic polymers has had a profound effect on society. Polymer systems have provided efficient and innovative materials for a broad range of applications and have been of paramount importance in increasing living standards and improving the quality of life. As is often the case with advancement, the need for materials innovation in polymer science has increased with time. In addition to the traditional needs of improved quality, increased efficiency, and reduced costs, concerns related to sustainability have led a revival and growth of interest in biobased polymers, with a strong focus on bioderivable or biobased precursors that can be synthesized in large measure from naturally sourced precursors.

Although polymers have been carefully studied for many decades, only a small fraction of the full design space of all synthesizable polymers has been explored. Vast regions of chemical space have yet to be synthesized and evaluated.

MedeA Polymer Expert, utilizes cheminformatics methodologies, combined with a comprehensive and carefully curated database, query, and search engines to provide an innovative and validated methodology for the exploration polymer property and chemical space.

This application note provides a summary of the use of MedeA Polymer Expert to address two example problems in polymer science.

32.1. Methodology

MedeA Polymer Expert employs a unique database, the Polymer Expert Analog Repeat unit Library, or PEARL, that has been constructed to be comprehensive in chemical and property space, and representative of systems which are not overly complex synthetically. PEARL contains more than 1.1 million repeat units and has a foundation comprised of a curated library of standard repeat units which have been reported and characterized in the scientific literature. MedeA Polymer Expert includes a query interface, a search engine, and reporting methodologies, which can be employed graphically, and on a background basis using the MedeA JobServer and Flowchart capabilities. The methodologies embodied by MedeA Polymer Expert are described in the MedeA documentation set, product datasheets, tutorials, research monographs [2] and peer-reviewed publications [3].

The application note summarizes two illustrations of the use of MedeA Polymer Expert as described below.

32.2. Identification of Possible PET Replacements

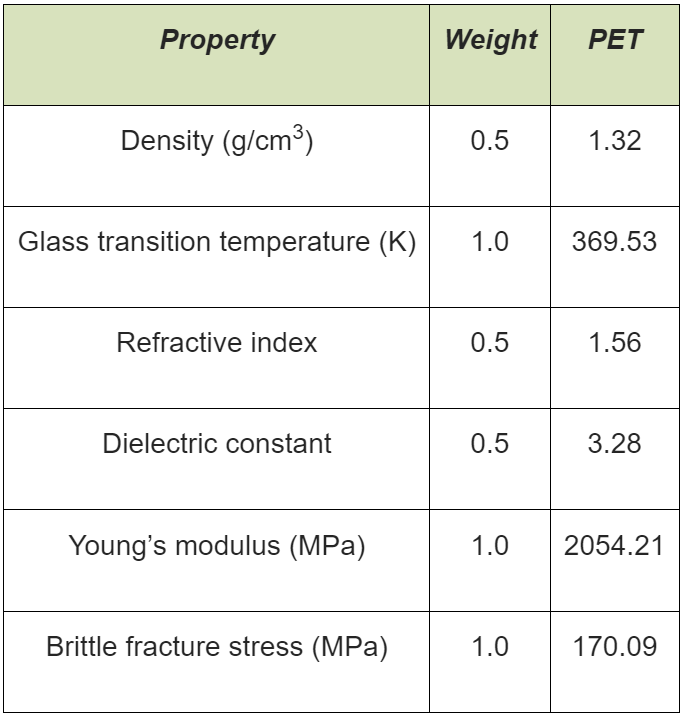

Employing a query based on 6 properties as shown in the following table, MedeA Polymer Expert used in a similarity search identifies the following bioderivable repeat units.

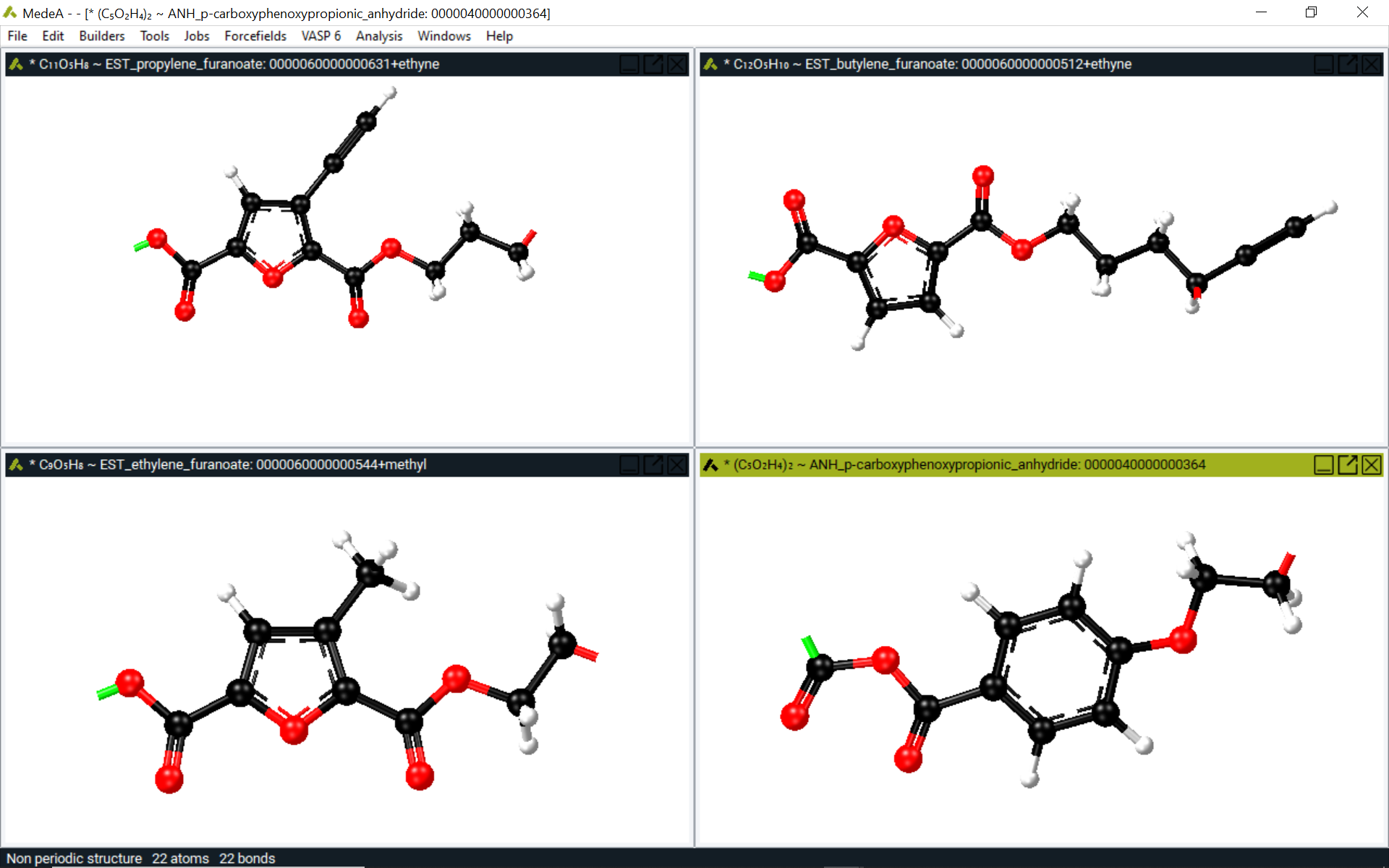

Figure 32.2.1 A selection of repeat units identified using the search criteria shown above includes polymers with multiple oxygens (red atoms), and aromatic moieties, as might be expected, and repeat units derived from furanoate (furan-2,5-dicarboxylate) units are among the search results. Poly (ethylene furanoate) (PEF) is an established biobased alternative to PET.

Among the results from this query are furanoate based olefin repeat units, which indeed provide a good correspondence with the typical PET properties listed above. Polyethylene furanoate, which is a bioderived polymer, is of course a well known potential replacement for PET.

32.3. Identification of Alternatives for Highly Crystalline Polypropylene Homopolymer (PPHP)

Highly crystalline polypropylene homopolymer (PPHP) exhibits high strength to weight ratio characteristics, excellent chemical resistance, a high degree of thermoformability, corrosion resistance, and no moisture absorption. As such, it is a very widely employed plastic. Nevertheless, the desire to improve sustainability, and the continued optimization of materials for consumer products, leads to interest in examining potential alternatives for PPHP.

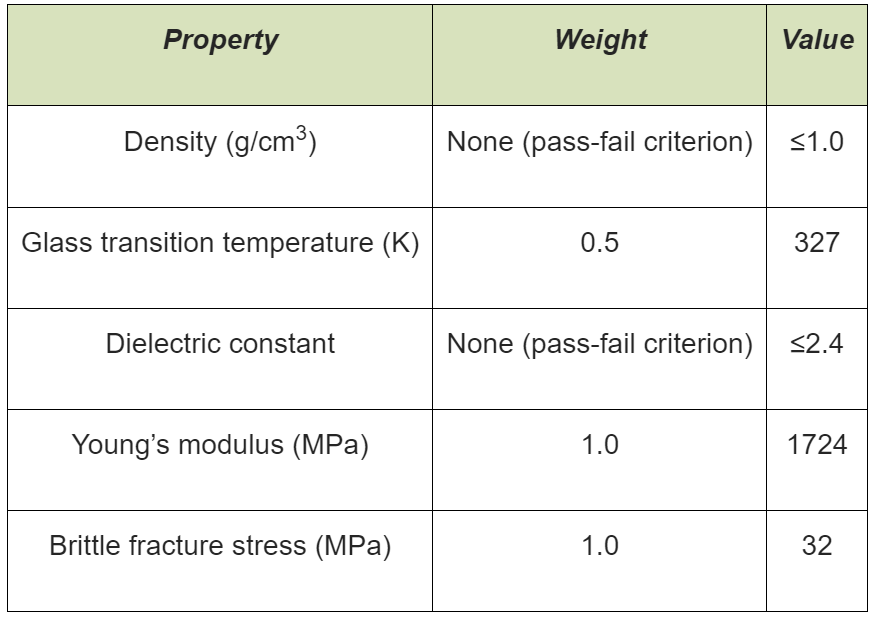

The property query shown below can easily be constructed and executed using MedeA Polymer Expert, leading to the search results illustrated in the subsequent figure.

Note that this query combines similarity based criteria, which employ a numerical weight, with logical criteria for the density and dielectric constant which must be obeyed for a result to be obtained for a given repeat unit.

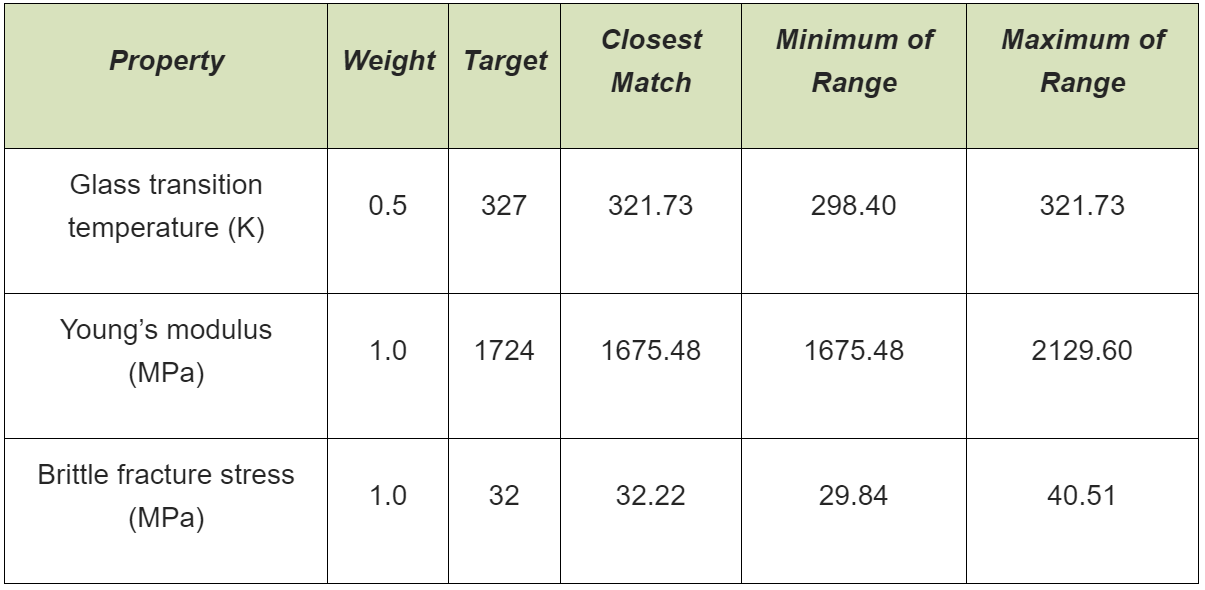

The following table shows a comparison of property targets (excluding properties for which only a pass-fail criterion is imposed) with values for candidates providing closest match, and the ranges obtained over 20 candidates providing closest matches in a search for PPHP alternatives.

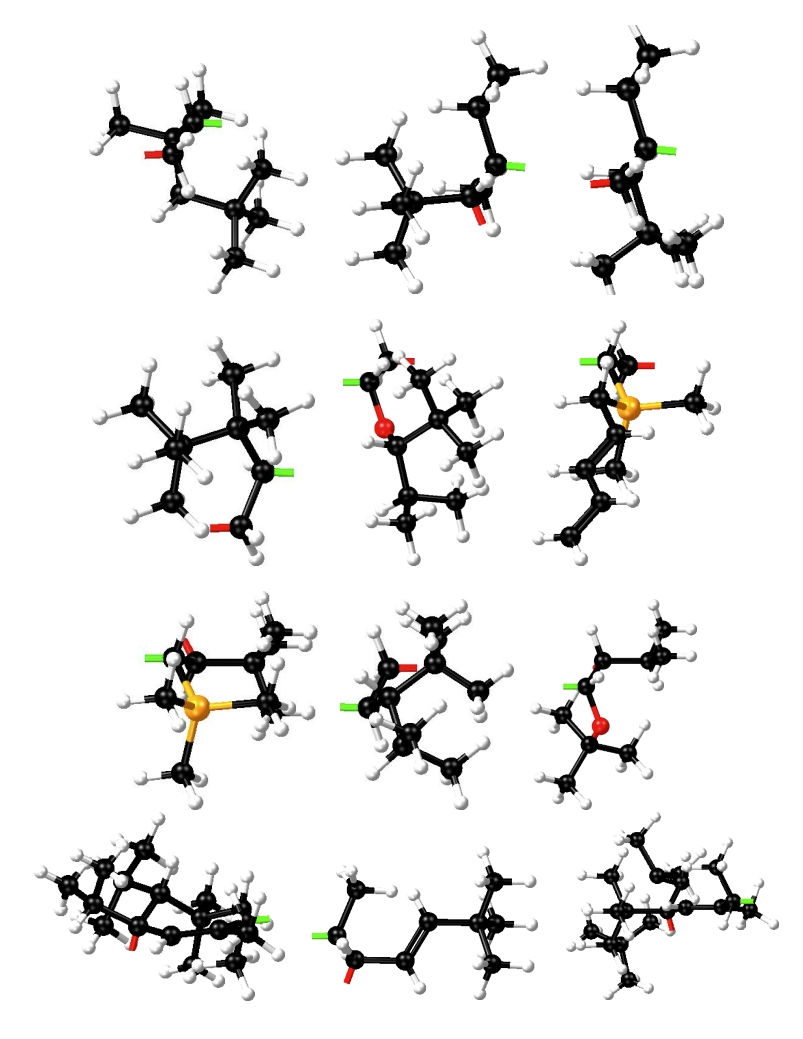

Figure 32.3.1 Repeat units from PEARL that provide close matches to PPHP in terms of the search criteria provided in the table above. These possible PPHP alternatives have large hydrocarbon (and some of them branched) side groups, and include some silanes (the gold atoms are silicon) and unsaturated groups. The search criteria limiting dielectric constants to 2.4 or less has the effect of eliminating many more polarizable repeat units, which typically contain oxygen and nitrogen atoms.

This example, employing the PEARL database to search for alternatives to PPHP, provides rapid insights into the types of repeat units to consider. MedeA Polymer Expert queries can be adjusted interactively to examine, for example, the sensitivity of search results to individual property criteria, such as in this case the dielectric constants used to exclude more polarizable repeat units.

32.4. Summary

MedeA Polymer Expert is a versatile and user-friendly tool for de novo polymer design, optimization, and analysis. As illustrated here, MedeA Polymer Expert, can be used to rapidly generate novel candidate repeat units to meet desired polymer performance targets.

The examples provided here involve the identification of biobased alternatives for poly(ethylene terephthalate) (PET), and the selection of possible alternatives for highly crystalline polypropylene homopolymer (PPHP). In both of these examples, many promising candidates were unobvious and unlikely to have been identified without using a polymer informatics approach.

MedeA modules used in this application

- MedeA Environment

- MedeA JobServer

- MedeA Polymer Expert

- MedeA P3C

| [1] | MedeA and Materials Design are registered trademarks of Materials Design, Inc. |

| [2] | J. Bicerano, Prediction of Polymer Properties, Marcel Dekker, Inc. (2002) |

| [3] | J. Bicerano, D. Rigby, C. Freeman, B. Leblanc, and J. Aubry, Polymer Expert - A Software Tool for De Novo Polymer Design, submitted, (2023). |

| download: | pdf |

|---|