MedeA P3C Polymer Property Prediction Using Correlations

At-a-Glance

MedeA ®[1] P3C computes a wide range of properties using empirical correlations for any desired thermoplastic polymer system. MedeA provides an extensive library of repeat units and MedeA P3C can use any sketched or standard repeat unit as input. MedeA P3C determines properties for polymer and copolymer systems using correlative methods. Additionally, the descriptors that MedeA P3C employs can be used to create ‘designer correlations’ for specific polymer types. These correlations maximize accuracy with restricted correlation scope.

Key Benefits

- Rapid evaluation of polymer and copolymer properties

- Establish the underlying molecular basis for key properties

- Validated correlations based on topological indices

- Designer correlations for targeted system analysis

MedeA P3C computes polymer properties using correlations. A particular merit of the MedeA P3C method is that it employs valence based descriptors, and is therefore more general than methods that rely solely on the presence of chemical groups and their mole fractions within target polymers. MedeA P3C is integrated within MedeA so you can access a large library of standard polymers, sketch any desired repeat unit, and rapidly compute properties. Interactively access results and compute properties with MedeA Flowcharts using the JobServer, in order to easily share results with coworkers. Employ MedeA P3C to compute the properties of both individual polymers and random copolymers.

MedeA P3C employs the core methodology described by Jozef Bicerano [2] sometimes known as the Synthia method originally developed at Dow Chemical. The MedeA P3C implementation extends the original methodology with a number of additional correlations for specific properties.

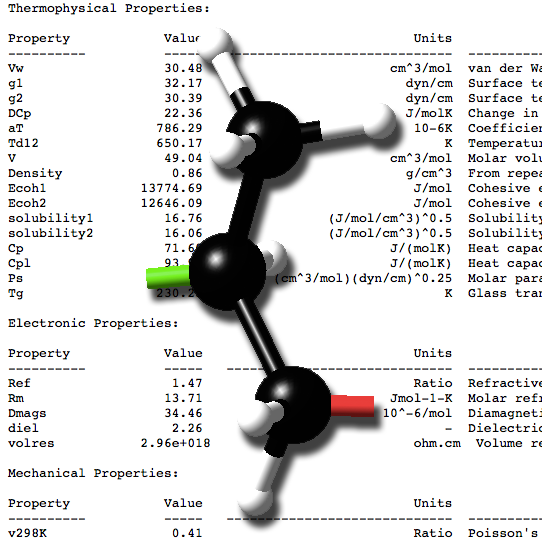

An interactive property calculation for polypropylene in MedeA showing a polypropylene repeat unit, with head (green) and tail (red) bonds, superimposed above an interactively updated property report. As modifications to the repeat unit are made using the MedeA molecular editor, the property report is updated in real time, providing an immediate link between structure and physical properties.

‘The ability to predict the key physical and chemical properties of polymers from their molecular structures prior to synthesis is of great value in designing polymers.’

Jozef Bicerano: in Prediction of Polymer Properties

Predicted Properties Include:

Thermophysical

- Glass transition temperature, Tg

- Temperature of half decomposition

- Change in molar heat capacity at Tg

- Coefficient of volumetric thermal expansion

- Cohesive energy

- Cp of liquid

- Cp of solid

- Density

- Molar volume

- Solubility parameter

- Surface tension

- van der Waals volume

- Thermal conductivity

Electronic and Optical

- Diamagnetic susceptibility

- Dielectric constant

- Molar refraction

- Refractive index

- Volume resistivity

Mechanical

- Brittle fracture stress

- Bulk modulus

- Poisson’s ratio

- Shear modulus

- Shear yield stress

- Young’s modulus

Entanglement

- Entanglement molecular weight

- Entanglement length

- Critical molecular weight

- Steric hindrance parameter

- Characteristic ratio

- Molar stiffness function

- Additive portion of molar viscosity-temperature function

- Activation energy for viscous flow at zero flow rate

- Zero-shear viscosity

Transport

- Permeability to CO₂, N₂, and O₂

- Zero shear viscosity

- Diffusion coefficients for N₂ and O₂

Key Features

- Reports a wide range of physical properties

- Supports interactive updates as structural modifications are made

- Computes the properties of sets of polymers using MedeA Flowcharts

- Provides access to property descriptors to create custom correlations

- Computes the properties of random copolymers as well as homopolymers

- Reports descriptors and computes properties for use in MedeA Flowcharts

Required Modules

- MedeA Environment

Find Out More

Learn more about how MedeA P3C provides polymer properties and materials design insights in the Materials Design Application Notes:

- Computing Polymer Properties Using Correlations

Learn more about building repeat units in MedeA here: How to Build a Polymer with Customized Repeat Unit

Learn about building extended polymer models in this online tutorial: How to Build a Polymer

| [1] | MedeA and Materials Design are registered trademarks of Materials Design, Inc. |

| [2] | J. Bicerano, Prediction of Polymer Properties, Marcel Dekker, Inc. (2002) |

| download: | pdf |

|---|