MedeA Thermoset Builder - An Advanced Tool for Building Densely-Crosslinked Polymer Models

At-a-Glance

The MedeA®[1] Thermoset Builder creates realistic models of topologically complex crosslinked polymer systems, as found in advanced aerospace and automotive composites, electronic devices, durable surface coatings, adhesives, and a variety of medical applications such as dental restoratives. Thermoset Builder is integrated with other tools within the MedeA Environment, and is optimized for use within the MedeA HT-Launchpad high-throughput framework. This enables maximum productivity when performing calculations on large batches of thermoset structures, as is required to obtain meaningful average properties of this class of material, which in practice can adopt a large number of energetically favorable configurations with widely varying bonding topologies (e.g. nature and degree of crosslinking). Thermoset Builder can be used to create models of densely crosslinked fully atomistic or mesoscale polymers, or incorporated into complex flowcharts within which crosslinking is preceded by building and equilibration of uncrosslinked material. This process is followed by calculation of properties of interest, such as mechanical properties, diffusion and/or sorption of gases or moisture.

Key Benefits

- Full integration into MedeA Flowcharts for batch processing, property averaging, and straightforward combination with:

- MedeA Amorphous Materials Builder, to create uncured starting materials

- MedeA-LAMMPS, for generation of dynamics trajectories

- Property calculation modules, for prediction of density (shrinkage), mechanical properties, and thermal conductivity using accurate forcefields

- Rigorous monitoring of material characteristics during crosslinking, including:

- Evolution of network structure and gel point

- Sol and gel characteristics

- Bond strain

- Automatic defect detection (for avoidance of unphysical ring catenations)

- Accounting for induced unequal reactivity (‘substitution effect’) in epoxy curing

- Ability to study a wide variety of combinations of resins and curing agents, with or without the presence of added solvent

Performance aerospace applications employ a variety of thermosets. Inset, the MedeA Thermoset Builder monitors local internal strain of the molecular structure as the model is being constructed.

‘Automated building of many hundreds of chemically realistic models of thermosets without having to create custom code or scripts is a welcome timesaver, allowing our group to focus on the ultimate goal of accurately predicting properties when searching for new high strength composite matrix materials.’

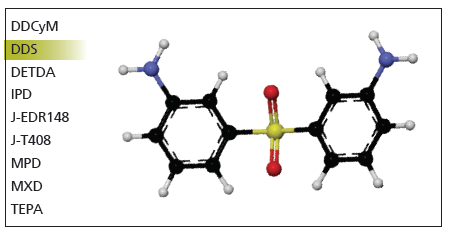

The builder creates models with any desired components, including the amine based curing agents shown here.

Create Realistic Models of:

- Epoxies

- Polyesters (alkyds)

- Cyanate esters

- Epoxy-Phenol-Novolac molding compounds

- Bismaleimides (BMI, polyimides)

- Polyurethanes

- Thermosetting acrylics

- Urea/ Phenol / Melamine-Formaldehyde plastics

Required Modules

- MedeA Environment

Find Out More

Learn more about how MedeA Thermoset Builder has been used in studies of composite materials by visiting the Materials Design Application Notes page on our website, and by reading the application note:

- Effect of Resin Molecular Architecture onEpoxy Thermoset Mechanical Properties

| [1] | MedeA and Materials Design are registered trademarks of Materials Design, Inc.

|