MedeA Software

Your Gateway to Computational Chemistry

The MedeA®[1] software package is the leading environment for the atomistic simulation of materials. MedeA enables professional, day-to-day deployment of atomic-scale and nano-scale computations for materials engineering, materials optimization and materials discovery. In MedeA, world-class simulation engines are integrated with elaborate property prediction modules, experimental databases, structure builders and analysis tools, all in one user-friendly environment.

An Integrated Solution

MedeA’s strength lies in combining experimental and computed data with modern informatics methods, user-friendly, graphical workflow building and sophisticated compute job management.

For a Broad Range of Applications

MedeA is used throughout many industries from academic research to industrial materials design and optimization, where atomistic modeling has become an integral part of the Computational Materials Engineering value-creation chain.

Virtually any Type of Material

MedeA methods and property modules address metals, alloys, semiconductors and insulators, organic solids, polymers, molecular systems and nano-structures. MedeA simulations cover crystalline solids and amorphous solids, fluid phases and fluid mixtures as well as solid/solid interfaces and fluid/solid interfaces. Computations cover a wide range of physical quantities and chemical phenomena spanning orders of magnitude in length- and time scale.

Design and Guide Experiments, Interpret Results

MedeA simulations help designing and focusing experiments. In addition, property data computed with MedeA provides guidance for interpretation of experimental results. Simulations offer great value, in particular when experiments are expensive, time consuming or difficult to perform.

Focus on Science

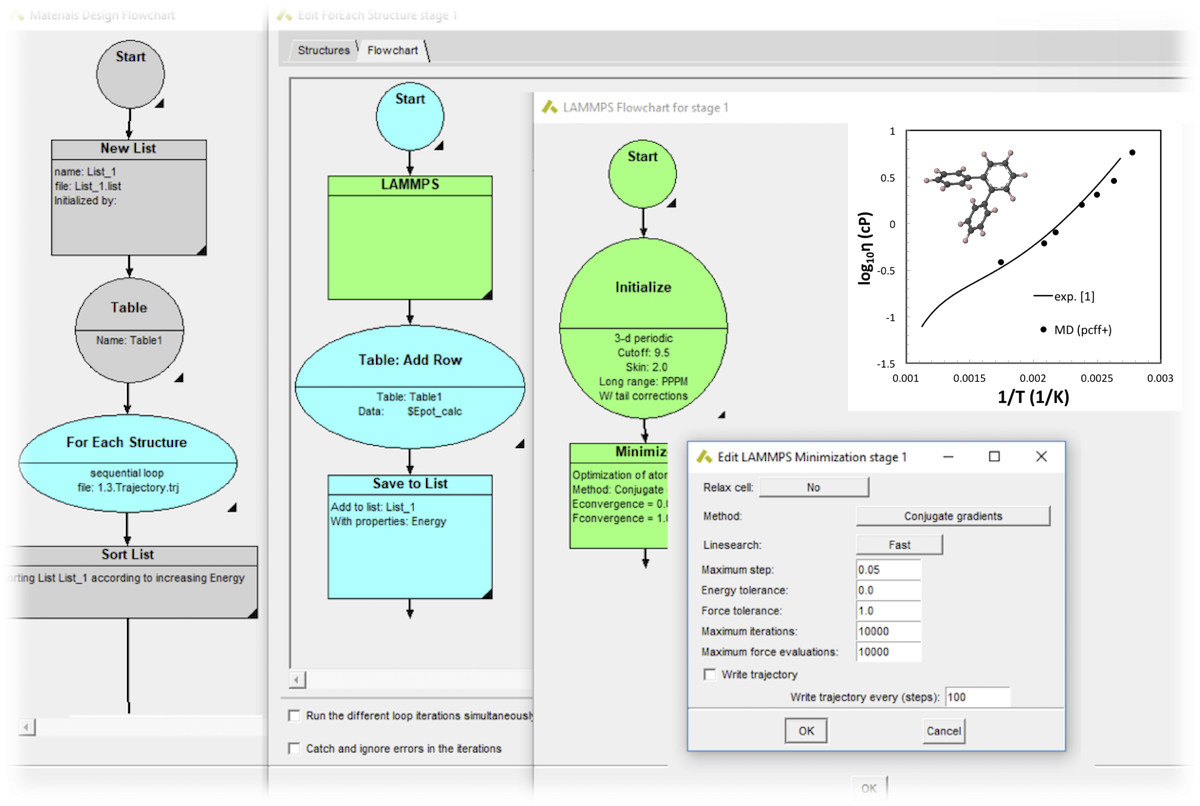

MedeA helps focus on key objectives such as materials screening, design of experiment and scientific analysis, rather than dealing with shell programming, file formats, command lines and syntax issues. Modeling materials or process parameters down to the atomic scale is greatly simplified through integration of all steps and parameter settings in one reusable workflow - from selecting a model system and setting up calculations to analyzing data and storing or sharing results.

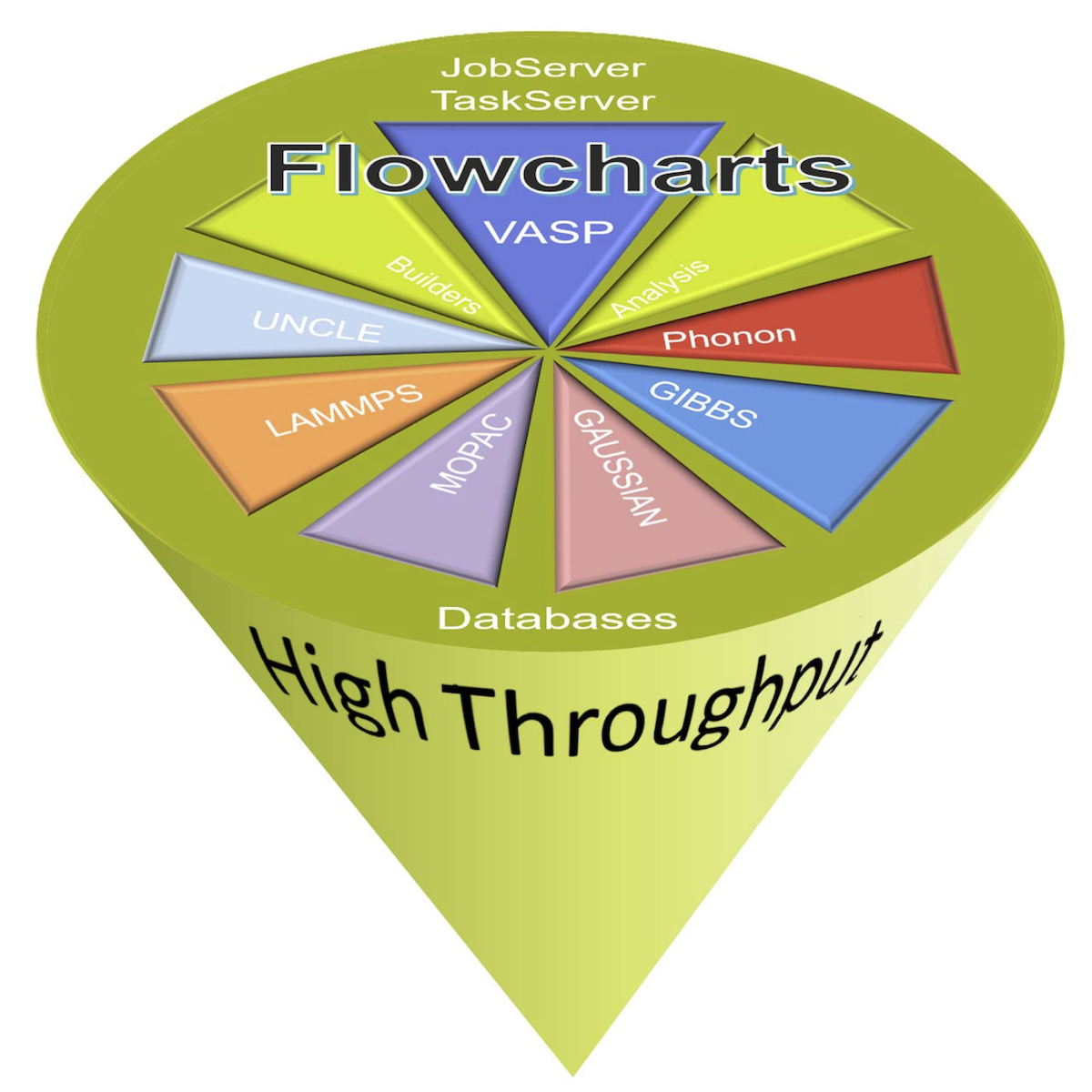

Create Sustainable, High-throughput Workflows Using Flowcharts

Putting elaborate compute protocols into action is simple when using MedeA’s flowcharts. Flowcharts contain full information about your compute jobs and because they are stored by MedeA’s JobServer, you can reload, share and refine them over time. A typical compute protocol may entail multiple stages deploying MedeA Builders, Property Modules, Engines, Analysis Tools and even custom code. In High-throughput mode, workflows operate on sets of data such as structure lists, trajectories or multiple configurations. In addition to handling large data sets and parallel tasks, MedeA’s novel high-throughput capabilities also include descriptor-based data mining and computational screening.

Learn more about MedeA: Databases, Builders, Compute Engines, Property Modules, High-Throughput and Analysis.

| [1] | MedeA and Materials Design are registered trademarks of Materials Design, Inc. |